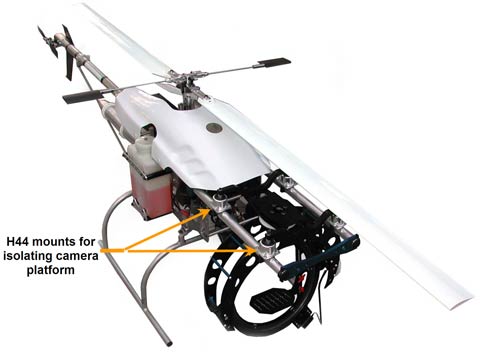

Low-frequency, friction damped mounts for high level vibration isolation and shock protection in rotary wing aircraft.

Barry H-Mounts are ideally suited for protecting equipment in helicopters or similar environments where high amplitude, low frequency vibration is predominant.

Downloads:

Contact us for special pricing on bulk orders over 25.

Filters Sort results

Reset Apply

Item # | Price | ||

|---|---|---|---|

H44-AA-1 | $99.07 | ||

H44-AA-3 | $99.07 | ||

H44-AA-4 | $99.07 | ||

H44-BA-1 | $99.07 | ||

H44-BA-2 | $99.07 | ||

H44-BA-6 | $99.07 | ||

H64-AA-15 | $108.88 | ||

H64-AA-20 | $108.88 | ||

H64-AA-30 | $108.88 |

FEATURES

- Axial to radial stiffness ratio of 4:1

- Friction damped spring

- For base mounting only

- Fail safe construction

BENEFITS

- IIdeally suited for protecting equipment in helicopters or similar environments where high-amplitude, low frequency vibration is predominant

- Increased equipment reliability and extended component life

LOAD RANGE

- H44 = 7 ratings from .25 – 10 lbs. per mount

- H64 = 7 load ratings from 2.0 – 40 lbs. per mount

APPLICATIONS

- Avionic equipment in propeller driven aircraft

- Equipment in environments where high amplitude, low frequency vibration is present

ENVIRONMENTAL DATA

- Operating temperature ranges of -67°F to +250°F (-55°C to +120°C).

- Designed for the rotary wing vibration requirements of MIL-STD-810B.

- Performs in attitudes up to 10° from horizontal.

- Meets vibration and shock requirements of MiL-C-172C.

| NATURAL FREQUENCY | 7-10 Hertz |

| TRANSMISSIBILITY AT RESONANCE | 2.0 Max. |

| RESILIENT ELEMENT | Friction damped spring |

| STANDARD MATERIALS | Aluminum |

| WEIGHT | H44= 1.63 oz. H64 = 3.56 oz. |